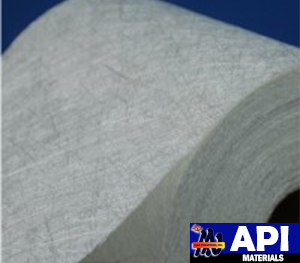

FIBERGLASS REINFORCED PLASTIC - FRP

API fiberglass is lightweight, has moderate tensile strength, and is easy to handle. Fiberglass is used in a wide assortment of projects within the industry, it may include: Rehabilitating existing structures and extending their life, Seismic upgrades, Defense systems, and many more.

Polyester, Vinylester and Epoxy ResinsPolyester resin is a thermosetting (cannot be re-formed post cure) used in a wide variety of applications. From figurines to fiberglass reinforced plastic (FRP) products, polyester resin is a versatile material.

Vinylester resin is used mainly for corrosive environments and application (e.g. chemical pipes, tanks, baths, trays, grating).

-

ADVANTAGES:

- 1) Cost effective especially for complex shapes

- 2) Last a long time

- 3) Weatherproof

- 4) Very good structural strength

- 5) Corrosion Resistant

- 6) Fire Resistant

- 7) Crack Resistant

- 8) Electrically non-conductive

- 9) Ability to be molded to precise tolerances

-

FIBERGLASS CAN BE APPLIED TO:

- 1) Marine Industries - Ships and Offshore platforms

- 2) Aerospace - Aircraft, Helicopters and Spacecraft

- 3) Civil Infrastructure

- 4) Automotive Industries

- 5) Construction Industries

Fiberglass is a versatile, strong, and durable material that has been widely used in various industries for its many beneficial properties. It is a type of reinforced plastic made from a combination of glass fibers and resin. These fibers provide strength and durability, while the resin acts as a binding agent. The use of fiberglass has been prevalent in industries such as construction, automotive, and aerospace. However, in recent years, there has been an increase in the demand for fiberglass in the chemical and food industries, leading to the development of chemical and food grade fiberglass.

Chemical grade fiberglass is designed to withstand the harsh conditions of chemical processing and storage. It is made from high-quality materials that are resistant to corrosion, oxidation, and chemical reactions. The fibers used in chemical grade fiberglass are specially treated to resist the chemicals they will come in contact with. Additionally, the resins used are chosen to provide maximum chemical resistance. This type of fiberglass is used in the production of storage tanks, pipes, and other equipment that comes into contact with various chemicals.

One of the main advantages of chemical grade fiberglass is its resistance to a wide range of chemicals. This makes it a popular choice for industries that deal with corrosive or hazardous chemicals. Unlike metal equipment, which can corrode or react with certain chemicals, chemical grade fiberglass is highly durable and does not require frequent maintenance or replacement. This not only saves time and money but also ensures the safety of workers and the environment.

Food grade fiberglass, on the other hand, is specifically designed for use in the food and beverage industry. It is made from materials that are non-toxic and do not react with food substances. The fibers used are specially treated to ensure they do not contaminate the food or alter its taste. The resins used are also chosen to be food safe, making food grade fiberglass an ideal choice for food processing and storage equipment.

One of the main advantages of food grade fiberglass is its high level of hygiene. Unlike metal or wood equipment, which can harbor bacteria and contaminate food, fiberglass is non-porous and easy to clean. This makes it an ideal material for food processing equipment, where hygiene is of utmost importance. It also does not require any coatings or sealants, which can potentially leach into the food and cause contamination.

In addition to its chemical and food resistance properties, fiberglass also has many other advantages that make it a preferred material for various applications. It is lightweight, yet strong and durable, making it easy to install and transport. It is also highly customizable, allowing for the production of equipment in various shapes and sizes to fit specific needs. Fiberglass is also a good insulator, making it suitable for use in both hot and cold environments.

Lastly, chemical and food grade fiberglass are essential materials in the chemical and food industries. They offer a wide range of benefits, including resistance to chemicals, hygiene, durability, and customization. As technology and manufacturing processes continue to advance, we can expect to see further developments in the use of fiberglass in these industries. With proper care and maintenance, chemical and food grade fiberglass can provide a cost-effective and reliable solution for various applications.