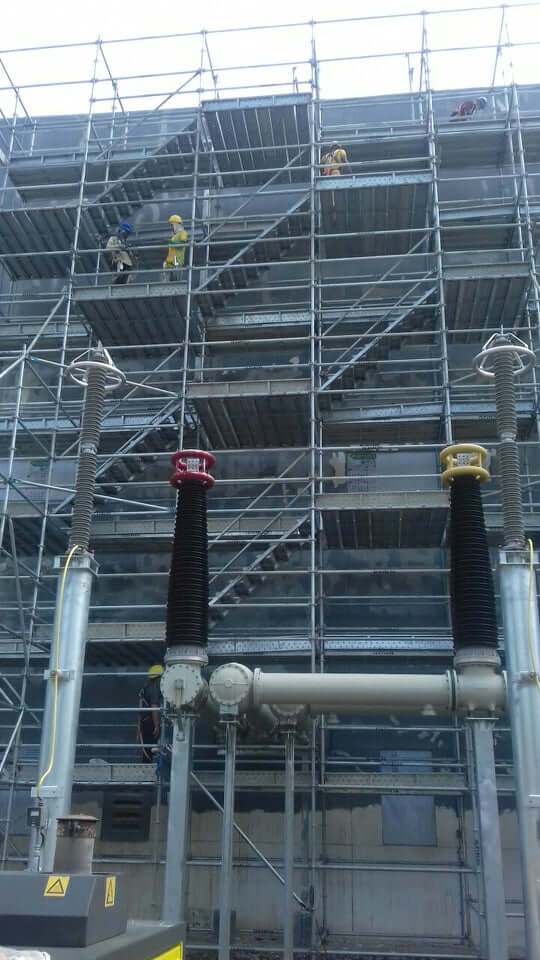

SURFACE PREPARATION

Expertise | What we do?

Surface Preparation is the process of treating a substance to increase its adhesion to coatings. It is the primary solution for abrasives, replacement parts, equipment, and services for both industrial and commercial surface finishing needs. It's primary purpose is to remove all contaminants by creating a surface profile to promote adhesion. It is done by choosing highly advanced and modernized equipment - The Professional Way.

AJAT Philippines, is the leading service provider in the Philippines. We offer the following services:

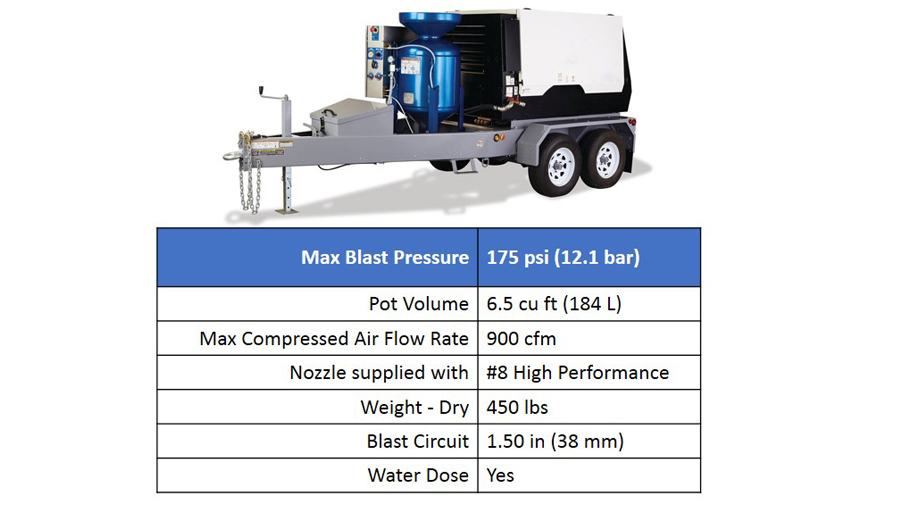

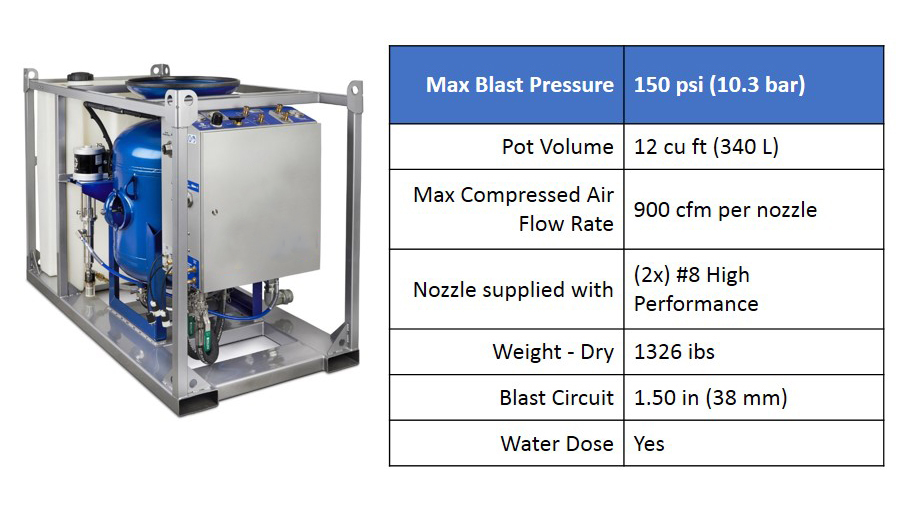

SANDBLASTING (DRY)

HYDRO BLASTING

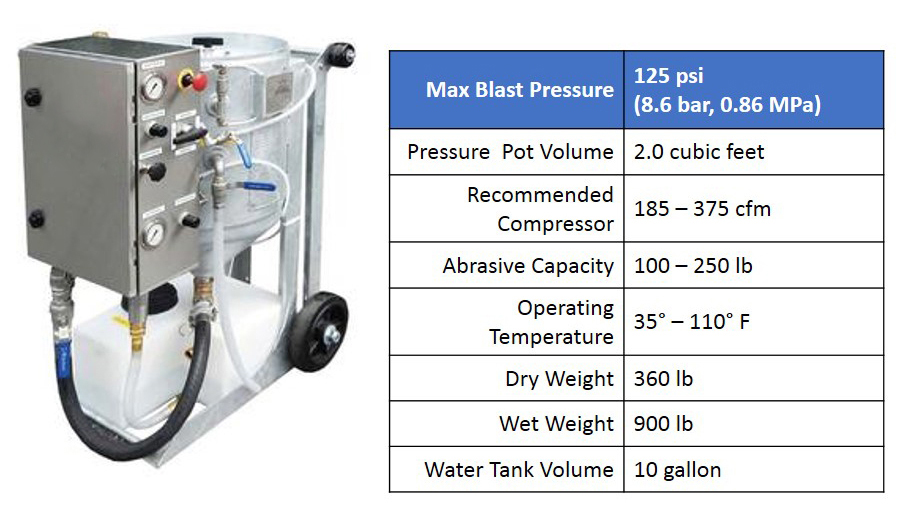

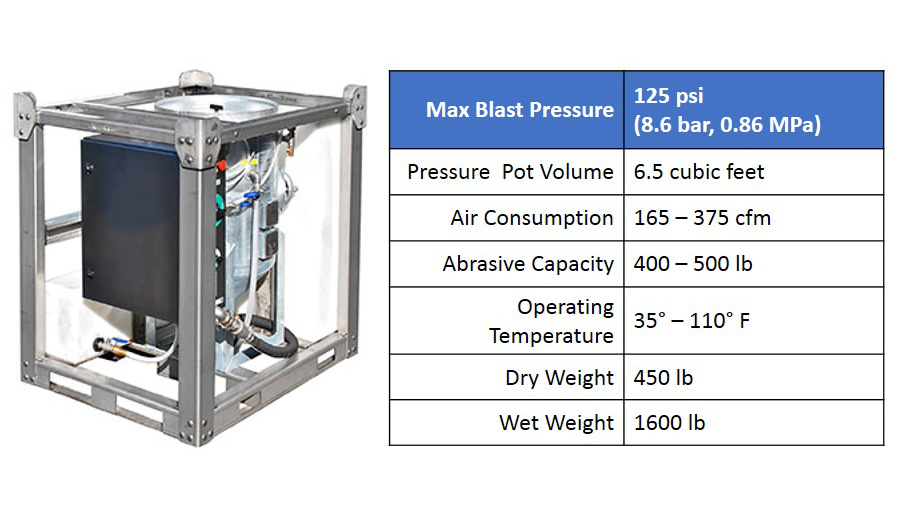

VAPOR BLASTING